Room Pressure Monitor Ball In The Wall

If you’re looking for a cloud-based air pressure monitoring sensor solution that eliminates manual logging, improves compliance readiness and protects all your clean rooms and compounding rooms, you’ve arrived at the right place.

Let us help you evaluate your needs!

- Safety: Alerts to protect asset

- Compliance: Automated reports

- Efficiency: Reduced Manual Logging

And what makes us different?

- Lifetime Warranty: Never buy hardware again!

- Unlimited Users: Scale across your entire org

- Connectivity Flexibility: Wi-Fi, Cellular or Data Hub

- Phone call alarms: Alerts won't get ignored

- Mobile App: 500 Freezers in your pocket

All American made and supported!

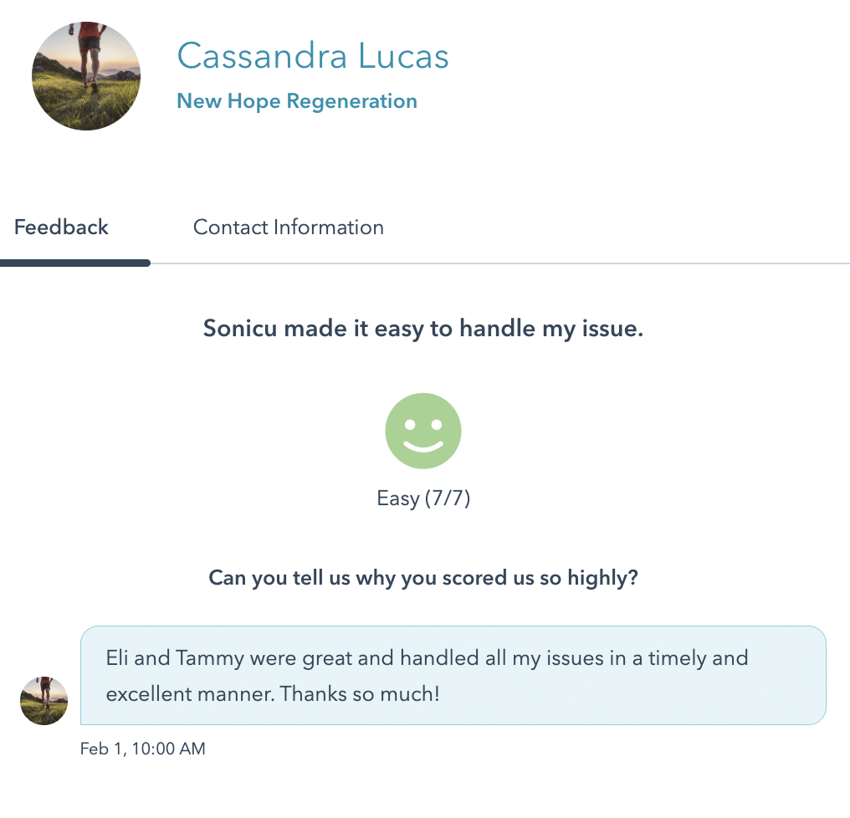

See What Customers Say About Sonicu

Asset Protection. Compliance Automation. And Reduced Manual Processes.

Sonicu serves thousands of professionals at hundreds of organizations across North America by improving how they monitor and manage their most sensitive assets and environments.

Professionals from healthcare, life science, laboratory and cold chain facility management turn to Sonicu to help them improve the way they do business.

Learn How Professionals Like You Improve With Sonicu™

Some of the finest names in healthcare and research, including Indiana University Health, University of Michigan Health System, Stanford University and Cryopoint, rely on Sonicu to provide robust continuous temperature monitoring for their cold and frozen environments.

These respected healthcare and research brands turn to Sonicu for three primary reasons:

- Operational Efficiency: Virtually eliminate the need for tedious and costly manual logging

- Compliance Automation: Respond to virtually any regulatory audit or inspection in a few clicks with our reports section

- Asset Protection: Detect and respond to any temperature excursion that can threaten virtually anything perishable: food, drugs, vaccines, research, etc.

Our customers on average save $80,000 per year for every 100 beds in their hospital.

Room Pressure Monitor Ball in the Wall

Many industries use different types of technology that are responsible for evaluating the environmental conditions within their buildings. These environmental conditions include but are not limited to aspects such as:

- Temperature

- Humidity

- Air pressure

- Sound

Why do these factors need to be monitored, and in which industries is this important?

Temperature, humidity, air pressure, sound, and other environmental conditions can impact staff, customers (or patients), and products in positive or negative ways.

When these conditions are consistent and the appropriate level of each is maintained, operations within a facility can continue as normal. However, when these environmental conditions become inconsistent or become abnormally high or low, there can be devastating consequences on the health, safety, and satisfaction of others.

One industry in which environmental conditions matter is healthcare. Environmental conditions are relevant to spaces like:

- Clinics

- Surgery suites

- Hospitals

- Health departments

- And senior living centers

Medications and vaccines are examples of products used in the healthcare industry that can be affected by the atmospheric qualities of the rooms they are stored in.

Many medications and vaccines need to be kept at certain temperatures (typically colder temperatures) for them to remain safe and effective for medical use.

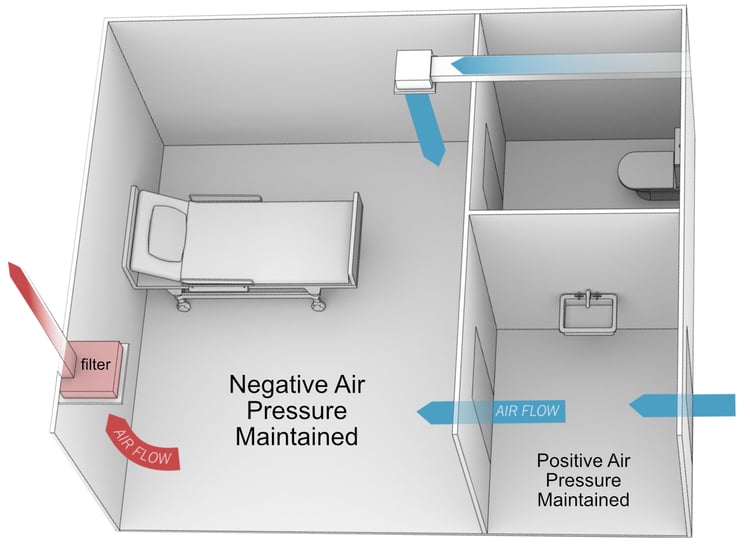

Another environmental condition that is important to regulate in healthcare facilities is air pressure, which in some cases is kept in a negative or positive range to either prevent air from leaving or entering a room, respectively.

Many hospitals monitor these differences in pressure by using a “ball in the wall” air pressure monitor. This kind of room pressure monitor (“ball in the wall”) is designed to indicate relative air pressure differential.

In this way, it acts as an airflow direction indicator that can tell medical staff whether the space or room they are in is at low or high pressure.

Ball in the Wall Air Pressure Indicator

A ball in the wall air pressure indicator is a crucial tool in many hospitals and other healthcare centers. As mentioned previously, certain situations or spaces require specific air pressure levels (high or low).

Spaces that have negative air pressure prevent air from leaving and traveling to other areas.

For example, isolation rooms tend to be kept at a negative level of air pressure because it can prevent airborne pathogens from escaping. Taking this precaution minimizes the risk that airborne pathogens and other harmful material in the air will come into contact with someone else, like a staff member or another patient in the hospital.

As such, having a ball in the wall pressure indicator is essentially non-negotiable in these settings so the safety and health of others are not unintentionally compromised.

In contrast, areas such as sterile rooms for operations tend to be kept at a positive level of air pressure. However, the reason is not to prevent air from escaping, rather it is a way to prevent outside air from entering.

In these circumstances, it is important to ensure that these spaces are not contaminated by things like the airborne pathogens and diseases previously discussed. Similarly, a ball in tube pressure indicator is typically necessary for these spaces to protect the health of the patient being operated on.

Ball Pressure Indicator

At first glance, a ball pressure indicator seems like a great tool or method for monitoring the air pressure in a way that complies with health and safety guidelines.

A ball in the wall room pressure monitor is a relatively inexpensive option and does typically meet minimal guidelines for compliance with standard safety procedures. However, a ball in tube pressure indicator does have some limitations in its capabilities.

A ping-pong ball air flow indicator will show one of two things:

1) the air pressure of the room does comply with regulations or

2) the air pressure of the room does NOT comply with regulations.

While this system does provide a way to quickly assess the compliance of a room at a specific point in time, it is not able to provide historical data describing the compliance of that same room over an extended period.

This means it is incredibly difficult to collect enough data to show a general trend in compliance.

The ability to see these trends on an hourly, daily, weekly, or monthly basis can provide insight into which areas a facility is lacking. In this same sense, this data can also provide evidence that problematic areas have been improved or are improving.

Ping Pong Ball Pressure Indicator

Another shortcoming of relying on a ping-pong ball pressure indicator for compliance confirmation is that it requires additional manual labor. To collect ball in the wall pressure indicator readings for each room, a staff member must be present to log those readings.

Typically, the staff member carrying out this task is also a healthcare provider or caregiver that has patients to tend to. This entails a great deal of walking the halls of potentially large hospitals, which takes time that could have been spent on more productive activities like treating patients.

While the floating ping pong ball explanation for the device in healthcare facilities is relatively simple overall, this simplicity comes at the sacrifice of detailed trends and time.

Aside from these aspects, the mere fact alone that a ball in tube pressure indicator requires manual labor at all leaves room open for human error to occur.

Even though the ping-pong ball air flow indicator itself is fairly accurate, the repetition of checking multiple devices and the fatigue that coincides with such a task can quickly lead to mistakes in logging readings.

What may seem like a small mistake could put the health and safety of patients and staff members in jeopardy.

Room Pressure Monitor Ball in the Wall

Considering how important it is to monitor airflow direction in healthcare facilities, are there any additional options for monitoring besides using the standard room pressure monitor (ball in the wall)?

As technology advances, more and more ways for reading and recording environmental or room conditions are coming to light. Today, rather than traditional “ball in the wall” installation, instructions, devices, and software are available to make the process more automatic and less reliant on human intervention.

In an attempt to find a more efficient way to monitor positive or negative pressure (room conditions), some hospitals and similar care centers have invested in automated room pressure monitoring systems.

This option removes the bulk of the human resources required to log air pressure differentials and replaces it with more sophisticated technology. However, many of these healthcare facilities run into a few issues when implementing this solution.

Most hospitals have a building automation system (BAS). To install one of these automated monitoring systems, it has to be able to integrate with the BAS used within the facility to allow for data to be shared.

There are often when the two cannot be integrated easily, at which point the installation takes more time and money than originally expected.

Room Pressure Gauge

At this point, it seems that the ideal solution is to discard the traditional room pressure monitor manual and system in exchange for an automated air pressure monitoring system despite the downsides.

For establishments that only want to monitor air pressure, this could be the optimal choice in comparison to the ping-pong ball air flow indicator. On the other hand, this option leaves out a large part of the needs of some healthcare facilities.

As was previously mentioned, establishments within the healthcare industry are often responsible for monitoring not only air pressure, but other environmental conditions like temperature, humidity, sound, and so on.

While an automated air pressure monitoring system may solve the problem of replacing the standard room pressure gauge, that is mostly the end of its work. In this scenario, it may be worth taking an additional step to wireless cloud-based monitoring.

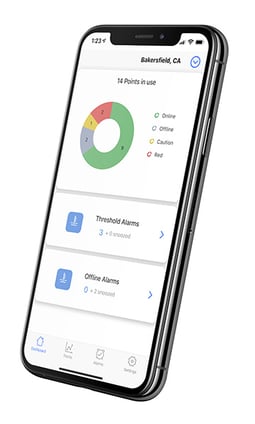

When it comes to air pressure specifically, Sonicu offers differential air pressure monitoring kits.

Unlike a traditional room pressure indicator, these kits are capable of monitoring air pressure 24/7, in real-time, and remotely. These kits come with a secure, cloud-based platform that logs data continuously, generates reports automatically, and sends out alerts when differential air pressure becomes incorrect or abnormal.

Visual Pressure Indicator

Sonicu provides several additional kits that can monitor other environmental conditions besides differential air pressure.

These kits are also compatible with the SoniCloud platform, which is the on-demand software that gives clients the ability to automatically monitor, alert, log, and report incoming data.

With these other kits, one can go beyond finding an alternative to the visual pressure indicator method.

In industries where multiple environmental conditions need to be monitored and a room differential pressure sensor alone may not be enough, Sonicu’s room conditions wireless monitoring kits offer a complete compliance solution.

This solution does not only provide a more effective room pressure controller or monitoring method, but it combines a variety of critical variable monitoring methods such as those for temperature, humidity, sound, and more into one unit.

These kits are easy to install and scale to the needs of different facilities. They are designed to accommodate the strict compliance regulations placed on sterile storage, hospital rooms, infectious control, laboratories, and more with a cost-effective solution.

Furthermore, beyond healthcare, these kits can also be used to conduct environmental condition monitoring in life science, university research, and pharmaceutical sectors as a way to help adhere to compliance requirements.

Sonicu has more than 500 customers in all 50 states and serves Healthcare, Health Sciences, Pharmaceutical, and Foodservice industries.

Customers trust Sonicu to monitor cold storage temperature, ambient room condition temperature and humidity, air pressure differential, and noise.

Our customers save on average about $80,000 per 100 beds while streamlining regulatory compliance from private and government agencies including the Joint Commission, FDA, CDC, VFC, State Boards of Pharmacy, and local boards of health.

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

“I like to say that every refrigerator or freezer is like a car in that they all behave a bit differently,

and then every now and then you just get a bad boy who doesn’t want to perform as we need it to,”

Martha Rardin, Director, Nutrition and Dietetics, Hendricks Regional Hospital.

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

“Sonicu has been a powerful tool to identify which units are behaving out of spec and get our team

to fix them before we have a serious issue.”

Tim Livesay, Director, Hancock Regional Hospital Pharmacy Director

Other Room Pressure and Condition Monitoring Resources

| Humidity | ||

| Alarm Handler | ||

| Surgery Centers | ||

| Distribution | ||

| Pressure | ||